Shop Talk

Direct from the Red Carpet in Las Vegas: A Superstar Machine for Midland

This past July, Midland’s Rob Boynton headed for the Association of Woodworking & Furnishings Suppliers (AWFS) trade show in Las Vegas with team members Jose Villalobos and Eric Martins. They didn’t come home empty-handed. Quite the contrary.

Happiness Is a New Machine

The AWFS trade show, an extravaganza of the latest products and technologies in the woodworking industry, is held every other year, and Rob Boynton makes a point of being there. This year’s trip was especially notable. Midland was picking up its hot-off-the-floor, advanced-tech, computerized and networked new wood beam saw.

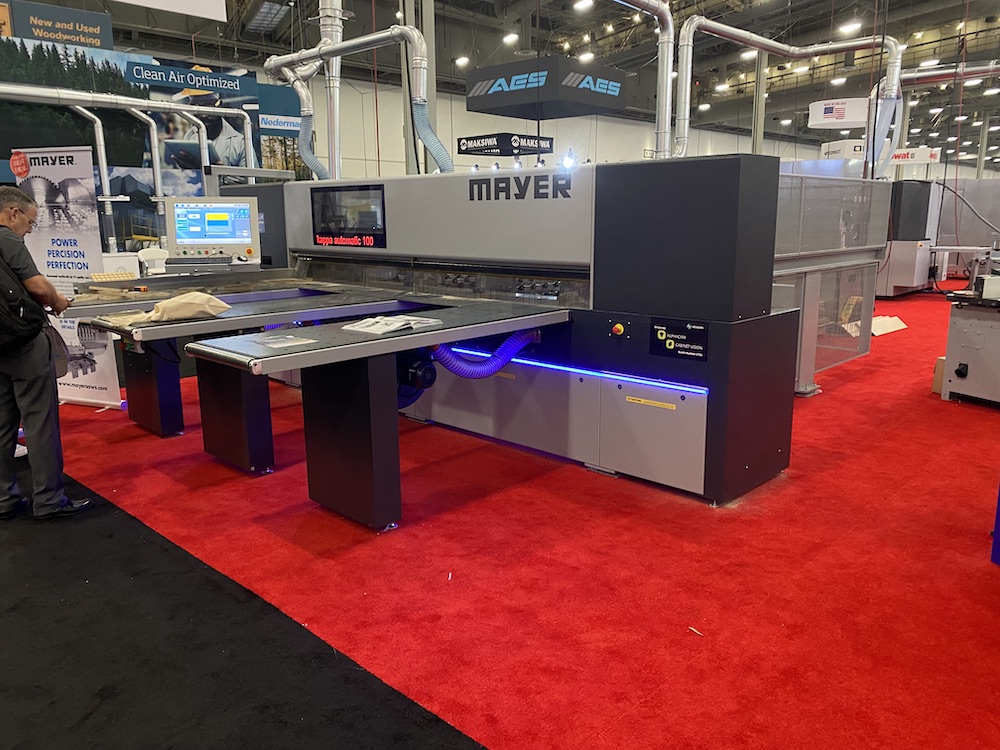

And not just any saw from any company. A Kappa Automatic from Mayer of Germany. Now joined with the Felder Group of Austria, the 2019 merger created one of the largest and oldest woodworking machinery specialists in the world.

Joining Rob were the people who would be working on the Kappa once the 7-ton mega-machine was delivered to the Midland fabrication shop in San Carlos. Eric Martins and Jose Villalobos also brought along their wives. “We went to dinner and had a great time,” said Rob. “It was a very special.”

Eric, cabinetmaker, and Jose, shop manager, also got a preview of how to operate the machine while it sat on the showroom floor before the massive machine was dismantled, shipped, delivered and reassembled at Midland.

“Everyone’s happy when we get a new machine,” agrees Rob.

Arrival in San Carlos

The new Kappa is not an unknown to Midland. Two decades ago, Rob and Sue Boynton went to the Mayer factory in Germany to pick out their company’s first automated beam saw from the same Kappa line. It’s been a workhorse, but times change. The replacement is that much more modernized after 20-plus years of manufacturing ingenuity. “It is a very sophisticated machine,” says Rob.

One feature is especially welcome for a busy, automated shop like Midland. The Kappa 100 adds a label, or barcode, to each piece of cut plywood. The label contains the instructions needed for how the next machine in the cabinetmaking process — a point-to-point machining center — will make the final cuts.

Thanks to the merger, the Felder Group CNC point-to-point machine and Mayer’s Kappa beam saw speak to each other remotely and both come equipped with keyboard and monitor for inputting and reading the technical requirements needed for each individual job. The specs are then engineered to near-perfection, according to Rob.

Installation at the Midland Fabrication Shop

Rob could have ordered the new Kappa direct from Mayer in Germany, but he chose to check out the local California dealer in Sacramento first. When he learned that the model he wanted was heading to Las Vegas to be a star in the AWFS show, a light bulb went off. It was going to be set up anyway, why not buy it here and forget about delivery from Germany.

“I got a discount, too,” says Rob, “because they didn’t have to send it back to Germany.” Another benefit: instant gratification.

The Kappa arrived unassembled on a Friday and was ready to go to work by Monday. All it took for the machine to start up was a phone call to Germany and the press of button. “I was standing there that morning and it just started up,” says Rob, still sounding awed by the smooth transition.