Room by Room: One in a series of articles by Midland on cabinetry design

Wood never ceases to amaze us for its beauty and utility, even after 50 years in the woodworking business. There are hundreds of woods to choose from; innumerable ways to use it. Without doubt, wood is a phenomenal material. The following is a basic primer on how we choose the wood we use in our fine designs. At Midland Cabinet Company, we don’t take wood for granted. We celebrate it.

Domestic and "Exotic" Woods

No matter where we get our wood, most of the trees we work with are hard, as opposed to soft, wood species, hard being the preferred grade for cabinetry, millwork, furniture and floors.

Hardwood, as its name implies, is dense and more durable; it doesn’t mar or dent easily, the attributes required for fine interior woodworking.

Of the domestic hardwood trees, oak is always a favorite, both red oak and white, which is slightly harder and considered a high-end material. Alder is popular, too, and it’s one of our favorites. Although not the hardest of the hardwoods, alder is a stain-grade wood, meaning it accepts a stain well and absorbs it evenly.

Other domestic hardwoods that make their way into our home designs: ash, American maple, cherry, beech, red birch and white birch, and hickory.

As beautiful as domestic wood is, exotic woods can take your breath away. More expensive than domestic wood, if the budget accepts the price tag there is nothing quite as awe-inspiring as a cabinet made of bubinga, or African redwood, a reddish-brown wood with an intricate, tight grain. Or wall paneling crafted from zebrawood, a lightly colored African wood with a riot of black striping. Not to mention cabinets and furniture crafted from one of the finest hardwoods in the world, Madagascar Ebony.

Sustainable Wood

Domestic trees are grown in U.S.-based plantations that manage the demand for the vast amount of wood the world requires. Another reason why we like alder: it’s a fast-growing tree, which means it is not in danger of being depleted.

Exotic woods may not be as carefully managed as domestic wood, though today consumers have a way to ensure that the wood they choose from Midland is sustainably grown: certification by the Forest Stewardship Council.

Reclaimed wood is another sustainable option. It’s not a newcomer to interior design: designers and architects have utilized recycled wood from old barns and bridges, even logs buried in water, for years to add drama and character to modern homes.

We’ve done quite a few jobs using reclaimed wood, among them a kitchen of rift sawn white oak timbers salvaged from a farm in Indiana. Ceiling, cabinets and paneling — basically the entire kitchen — were fashioned from the farm’s vintage barn, giving the room a warm, rustic and inviting atmosphere.

Veneer Matching

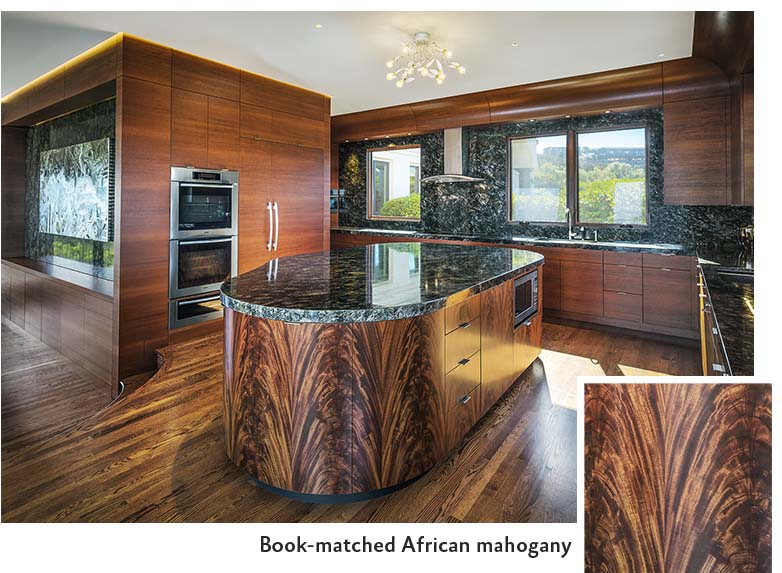

The way the thin sheets of veneers are spliced together to create a veneer’s distinguishing appearance is called matching. At Midland, we use three primary matching styles: book matching, slip matching and center balanced.

In book matching, alternating pieces of veneer are “flipped over” so that they face each other, like a butterfly, or, as its name implies, like facing pages in a book. In slip matching, the veneer slices are placed in sequence, not flipped.

Center balanced is the most aesthetically pleasing and the most intensive for the woodworker. Here, we assemble uniform sheets of veneers around a joint, or vertical splice line, in the middle of the panel to create a symmetrical grain pattern. Center-balanced matching is a dramatic way to display the grain, and its symmetry can enhance the overall design of the room.

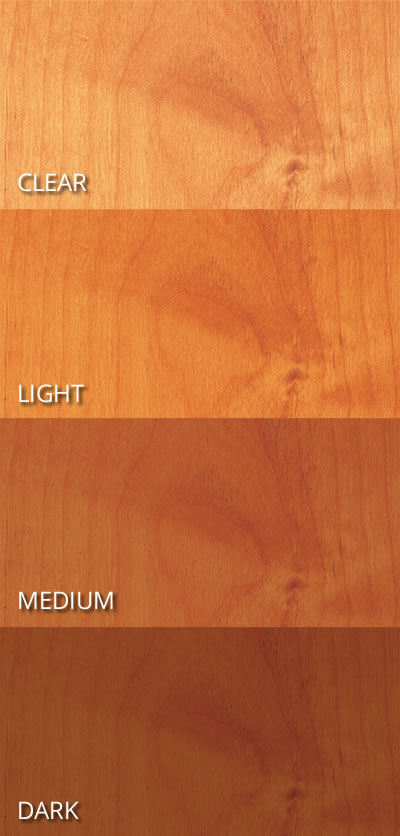

Alder (Ainus rubra)

Grown in abundance in the Pacific Northwest, alder is a popular domestic hardwood. Almost white when cut, alder wood darkens with exposure to air.

Closeup of the reclaimed wood used in the kitchen shown here.

Blueprinting

In some high-end jobs, clients want a consistent look in the veneer paneling throughout the room — on all the cabinets and the wall paneling, for example. To ensure this uniformity, we rely on blueprinting, which, as its name implies, is a detailed, to-scale drawing of the veneers to be used on a project.

Blueprinting is an exacting woodworking science, and successful only in the hands of experts. It takes skill and expertise to render a blueprint — and years of experience — to ensure the perfect harmony of grain and balance.